| |

mineral selecting equipments

|

|

|

Brief Introduction

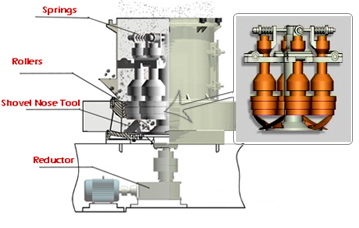

MTM Medium Speed Trapezium Mill is a leading-world-level industrial mill. It is designed by our own engineers and technical workers, basing on industrial mill research of many years and adopting world-leading-powder processing technology. Our machine adopts many advantages from numbers of mill all over the world, such as trapeziums working surface, flexible connection, roll linked pressure boost, etc. It has overcome the traditional mills defect completely in application, capacity, fineness, energy consumption, service life, etc.

And it is the ideal substitute of the traditional mill, such as Raymond mill, high pressure suspension mill, ball mill, etc. Nowadays, our products have been widely used in metallurgy industry, electric power industrial, chemical, building, steel industry, coal industry, etc. And it has brought large economic benefits to our customers and the society. |

|

Working Principle

Air is driven into the undersurface of the grinding ring and flows upward, carrying fines to the classifying section. The classifier allowed the pulverized material to pass and the oversized particles are drove back to the grinding chamber for further processing. The whole mill operates under negative pressure conditions, which can maximize the service life of major mechanical components. Thus minimizing mill maintenance and plant housekeeping problems have been solved. |

|

Technical Advantage:

1、The ladder-shaped rollers and rings improve crushing efficiency greatly. The rollers and ring are designed in the main machine of an inverted trapezium, which control the material’s slip velocity between rollers and rings. They can extend the grinding time, and enhance the crushing effect.

2、The press springs with balancing and pressurized function and the forming resilient connection with steady and vibration reducing function are invented into our machines.

3、The powder classifier adopts high density impeller, which can increase precision of powder and capacity.

4、There is high-efficiency and energy-saving blower installed on our machine. The efficiency of prismatic blade equipped on the traditional machine is only 62%, but the efficiency of the energy saving blower, whose impeller and blade are both stamping, is 85%.

5、There is convenient impeller adjusting device. The clearance between housing and ending of powder classifier’s blade also effects fineness. Our mill is convenient to adjust the fineness. |

| Table1 |

| Ite |

MTM100 |

MTM130 |

MTM160 |

| Number of roller |

4 |

5 |

6 |

| Major diameter of roller ×Height(mm) |

Φ320×200 |

Φ410×240 |

Φ440×270 |

| Internal diameter of roller × Height(mm) |

Φ980×200 |

Φ1280×240 |

Φ1600×270 |

| Maximum feeding grain size (mm) |

130 |

103 |

82 |

| Maximum feeding grain size (mm) |

<25 |

<30 |

<35 |

| Grain size of finished product (mm) |

1.6 -0.038 |

1.6 -0.038 |

1.6 -0.038 |

| Output (t/h) |

3 - 8.8 |

6 -13 |

13 -22 |

| Overall dimension (mm) |

9910×5365×8310 |

7910×7000×9645 |

12550×5700×8355 |

| Weight(t) |

16 |

26.1 |

35 |

|

| Table2 |

| Name |

Item |

Unit |

Specification and technical data |

| MTM100 |

MTM130 |

MTM160 |

| Motor of main engine

|

Model |

- |

Y225M-4 |

Y280S-4 |

Y135M1-4 |

| Power |

kw |

45 |

90 |

132 |

| Spindle speed |

r/min |

1480 |

1480 |

1480 |

| Motor of adjustable varying speed motor |

Model |

- |

GZT2-42-4 |

YCT200-4B |

JZT2-52-4 |

| Power |

kw |

5.5 |

7.5 |

11 |

| Spindle speed |

r/min |

125~1250 |

125~1250 |

125~1250 |

| Motor of

elevator |

Model |

- |

Y1000L-4 |

Y1000L2-4 |

Y112M-4 |

| Power |

kw |

3 |

3 |

4 |

| Spindle speed |

r/min |

1420 |

1420 |

1420 |

| Motor of centrifugal induced draught fan |

Model |

- |

Y225S-4 |

Y250M-4 |

Y112M-4 |

| Power |

kw |

37 |

75 |

110 |

| Spindle speed |

r/min |

1480 |

1480 |

1480 |

| Motor of jaw crusher |

Model |

PE |

200x350 |

250X400 |

250x400 |

257x750 |

| - |

- |

Y160M-6 |

Y180L-6 |

Y180L-6 |

Y200M-6 |

| Power |

kw |

7.5 |

15 |

15 |

22 |

| Spindle speed |

r/min |

970 |

970 |

970 |

| Magnetic vibration-actuated feeder |

Model |

- |

GZ1F |

GZ2F |

GZ3F |

| Spindle speed |

watt |

60 |

150 |

200 |

|

|